T34 Cooling Jacket

Post Machined Cooling Jacket with o ring grooves for sealing requirements.

Introduction

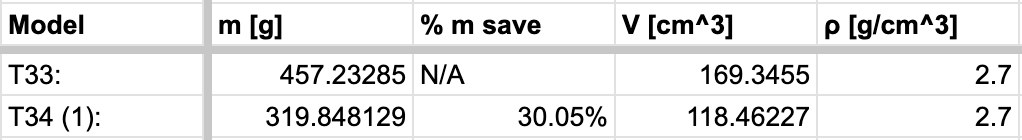

During my freshman year on the UW FSAE team, I was recruited to the drivetrain team, where I was tasked with innovating the new concept cooling jacket. This part encompasses each of our four electric in-hub motors and dissipates heat via a water cooling system. The project offered significant room for creativity and development. My primary goals were to test the system and verify CFD simulation, improve ease of assembly through O-ring modifications, and achieve significant weight reduction, while still producing a model that is 3D printable without supports. Through a rigorous design process, the final product achieved a 30% weight reduction while maintaining similar pressure drop and temperature delta at the inlet and outlet (verified by CFD & testing). This reduction in unsprung mass and validation of motor cooling contributed to the UW FSAE car placing 3rd overall in 2023.

T34 Drivetrain Package

Cooling Jacket integrated into the drivetrain package – attached to the uprights via motor mounting plate.

Weight Reduction

O-Ring Changes

The maximum load on this part occurs at the top O-ring groove during assembly. The wall thickness will be reduced from 2.0mm to 1.5mm, as simulated in ANSYS Static Structural with a reasonable factor of safety.

The O-rings have been changed from 2.5mm diameter, 75A durometer, to 1.8mm diameter, 70A durometer, to enhance ease of assembly while maintaining the same compression ratio and reducing groove fill from 75% to 70%.

Channel Design

The design utilizes Circumferential Channels instead of Helical or Axial Channels based on ANSYS CFD analysis of contact area and heat transfer coefficient.

Success At Competition

During the annual FSAE competition in Michigan, the cooling jackets performed as expected, and the car finished 3rd overall.

Leave a comment