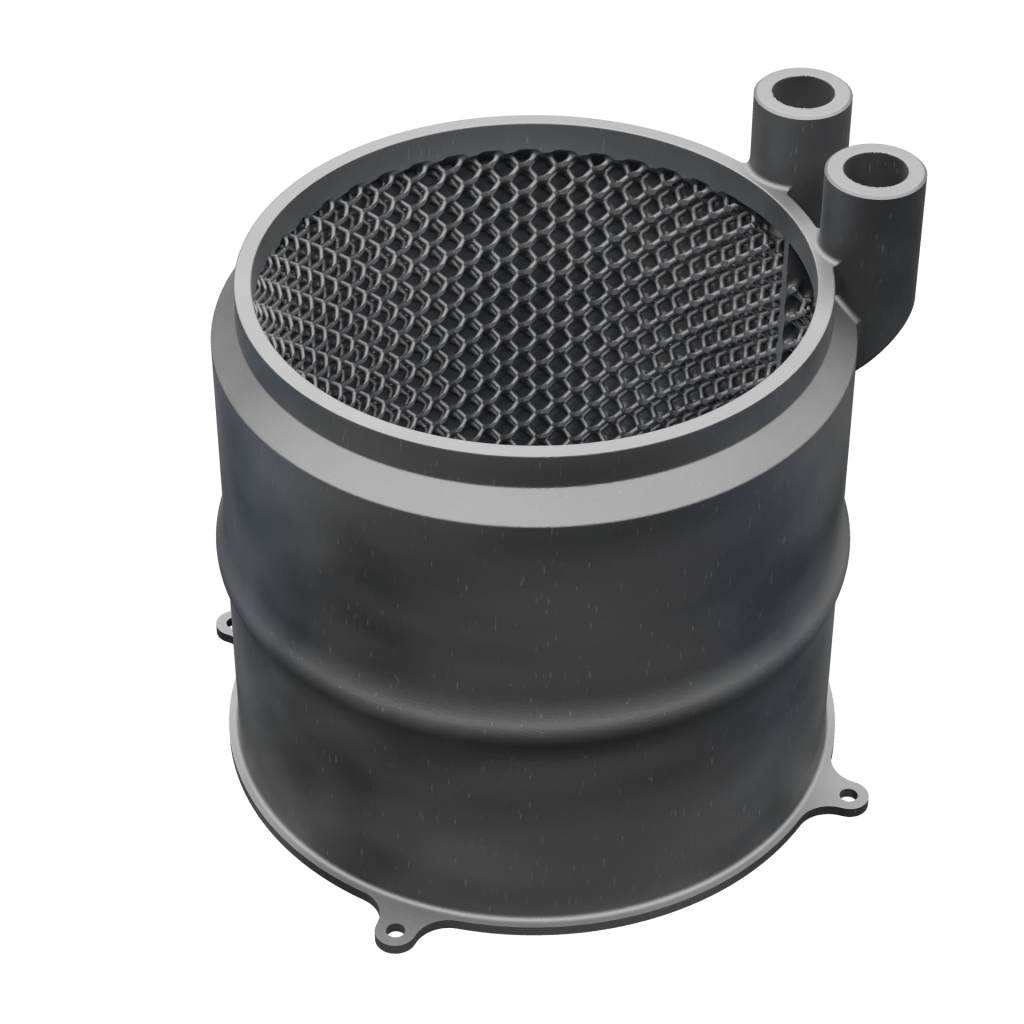

T35 Cooling Jacket

Printed T35 Cooling Jacket showcasing internal diamond lattice structure

Introduction

While the T34 cooling jacket successfully helped carry the FSAE car to the podium in the 2023 competition, significant improvements were still needed. One issue was that our mass flow rate sensor indicated the flow rate was too low. To address this, I calculated an optimal pressure drop of 25 kPa to optimize the cooling jackets. My focus then shifted to enhancing the jackets for better inlet/outlet pressure delta, temperature delta, and overall cooling efficiency. The resulting design utilizes DMLS technology without supports, featuring an internal diamond lattice with variable thickness tailored to specific cooling needs across the jacket. Thickness is determined via point map generated from ANSYS and manipulated with python scripts, resulting in thicker lattice at points where the motor is cooler and velocity is slower. This structure also led to a smaller OD and a 16% weight reduction.

T35 Drivetrain Package

Cooling Jacket integrated with the rest of the T35 drivetrain package.

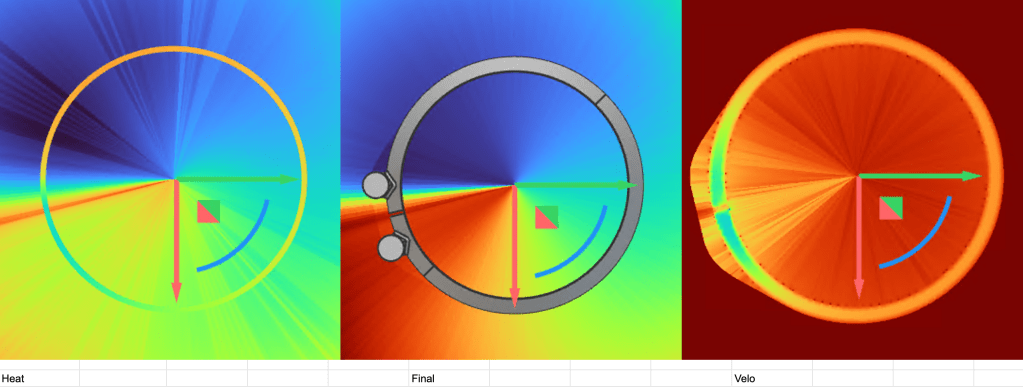

Determining lattice thickness

Lattice thickness is determined using a point map corresponding to points in 3D space, with scalars assigned between the minimum and maximum beam thickness. Utilizing nTopology, the lattice structure can be created with this point map information in minutes.

Success At Competition

After a full year of research and production, the University of Washington’s T35 FSAE car secured 1st place in the endurance competition—a 22km event where drivers push their cars to the limit, truly testing cooling capabilities. The cooling jacket kept the motors 25°C below the torque-limiting threshold, allowing the car to not only finish the event intact but also achieve the fastest time.

Leave a comment